Heating & Cooling System is 60% open by perforated metal sheet which ensures maximum surface exposure for better cooling. The heater band is covered with Blower cover for mounting the Blower. Advantages of air cooled over liquid cooled operation includes lower cost, easy replacement, low maintenance, no leakage problem and uniform temperature control.

Additionally, Heating & Cooling Systems do not require an expensive cooling tower or heat exchange system, extensive plumbing systems and labor for installation. These factors along with the benefit of being maintenance free make Air Cooled Band Heaters an economical and practical source for your extrusion heating and cooling application.

| SPECIFICATIONS FOR AIR COOLED CERAMIC HEATER | |||

|

Coil Heater

|

Item No. | PM-ACCH | |

| Wattage | Customized | ||

| Voltage | 110 V -480 V | ||

| Working Temperature | Intermittent operating max. temp | 815°C | |

| Continuous operating temp | 550°C | ||

|

Dimension

|

Minimum diameter | 30 mm | |

| Diameter tolerance | -0.1mm to -1mm | ||

| Width tolerance | +/- 1 mm | ||

Main Features

1) To heat and cool the barrel

2) Low Maintenance

3) Easy Replacement

4) Improves Quality of finished products

5) Space Saving

6) Increases Productivity

7) Available with Various Diameter, Length, Voltage, Wattage and Configurations.

|

Air cooled ceramic heaterName: ceramic heater / ceramic band heater / ceramic heater with shroud / air cooled ceramic heater Brand: PAMAENS Material: 1. Cr20Ni80, high quality Swedish resistance wire is available 2. High quality ceramic insulator 3. SS304 4. Connection box |

|

Air cooled ceramic heater with ceramic finsName: ceramic band heater with fins |

|

Air cooled ceramic heater with copper finsName: ceramic heater with fins |

|

Air cooled aluminum heater

Name: aluminum band heater

|

Pre-Sales Service

- Flexible MOQ

- Fast and on-time delivery (normally within 15 days)

- Free replacement if any quality issues within guarantee period.

- After-sale services

- OEM and ODM service

After-Sales Service

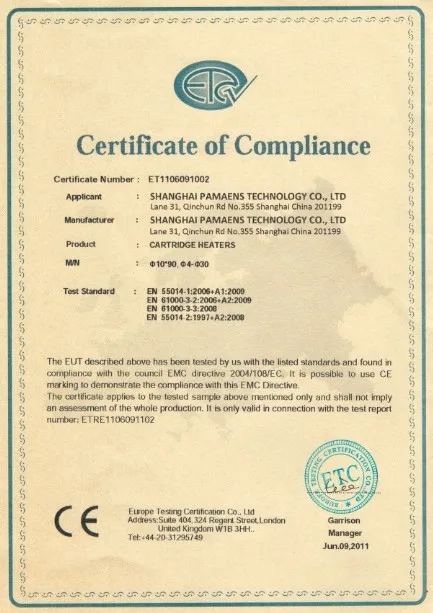

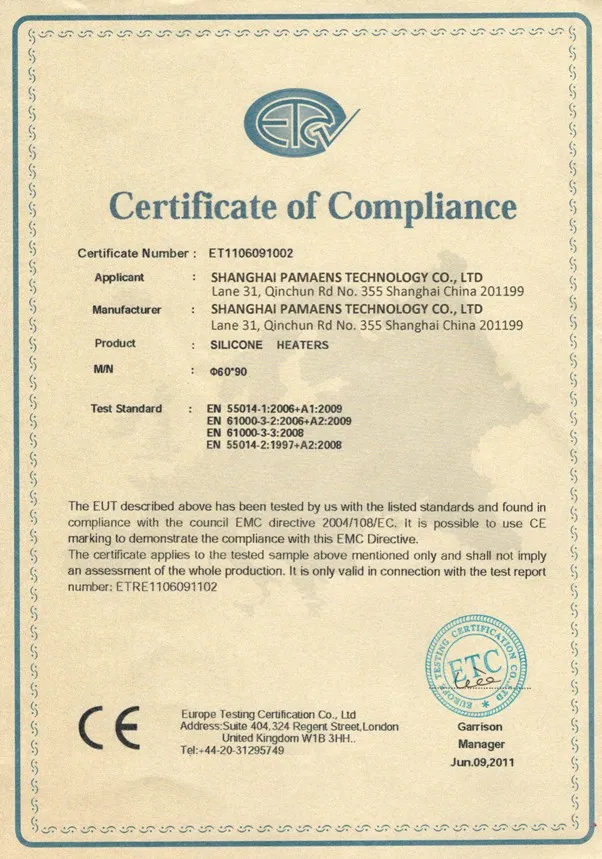

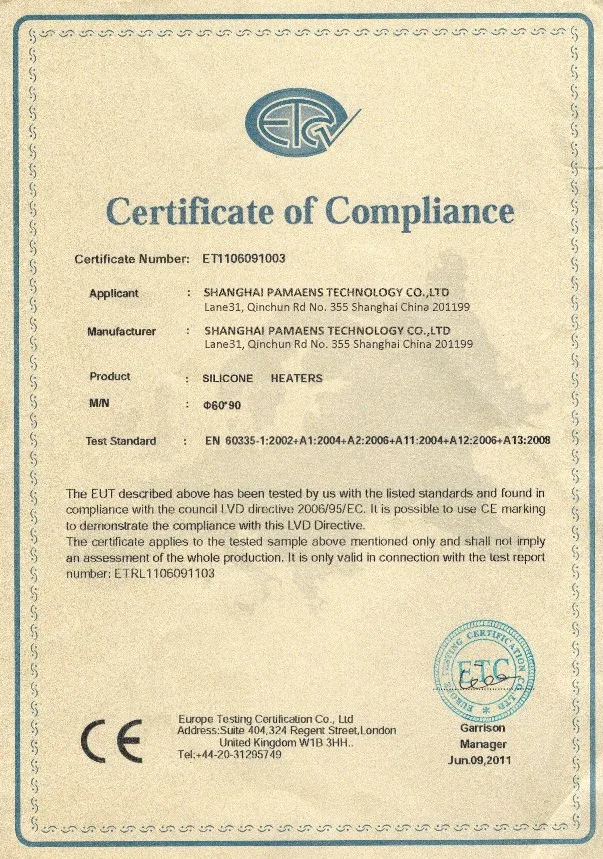

PAMAENS has strict quality control system on material sourcing, manufacturing processing, and products testing. We insist on using high quality raw material and inspect all the materials we will use. We do 100% product testing before shipping, the test includes x-ray inspection, rated power and voltage testing, cold insulation resistance test, leakage testing, pressure test, surface temperature uniformity and various electrical testing.

We provide one year warranty for most of our products, free replacements or refund could be applied if our customers have any quality problem within one year.