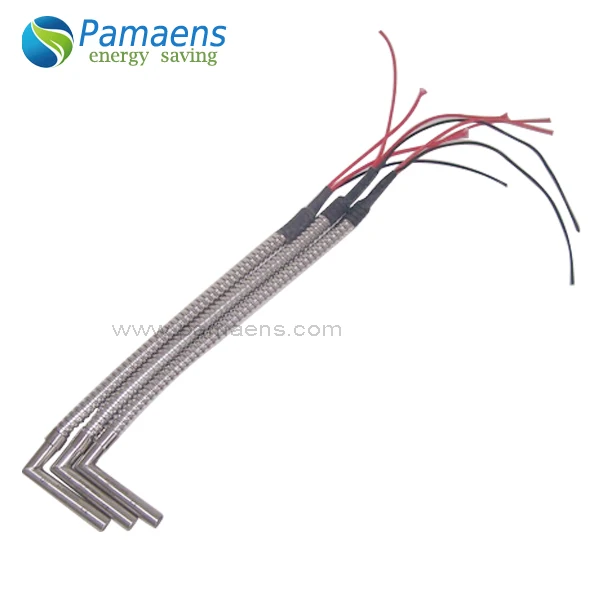

Description of Cartridge Heater Element

Cartridge Heater Elements are used largely used to heat liquid, solid or gas, the application in plastic industry is very wide, such as hot runner system,small mould heating ,plastic package ,Medical equipment plastic ,plastic injection molding machine nozzle heating, Package and cartridge is also used in the cigarette industry, footwear industry, thermoforming machinery. Small cartridge heaters are largely used for heating 3D printers, which has high wattage density, and could heating up fast and efficiently. We could make the cartridge heater as small as 1mm in diameter, 15mm in length, voltage from 6v to 480v. Wattage density could be as high as 20w/square cm.

Cartridge Heater Elements belong to a new generation of electric heating elements; they make it possible to use high watt loads in small spaces, thus ensuring excellent reliability in heavy-duty work conditions. Their special construction technology makes them the most advanced type of heating elements. The entire length of the wire wound around a magnesium oxide core is in a faraway position from the axis of the cartridge, very close to the metal sheath, with a very thin and compressed insulating wall in between; this allows excellent heat exchange that allows a much lower temperature of the resistance wire than in other heaters in which the wire is in a deeper position. Besides the use of advanced technology and precise inspection techniques in their manufacturing, cartridge heater owe their total reliability to the use of first-class material from the best sources in the market.

Datasheet of Cartridge Heater Element

| Sheath material | SUS304,321,316,Incoloy800,840 |

| Wattage Tolerance | +5%, -10% |

| Resistance tolerance | +10%, -5% |

| Voltages available | 6v – 650v |

| Max operating temp | 800ºC |

| Length tolerance | ±1 mm |

| Diameter tolerance | -0.02mm |

| Standard Cold Zone | 5-10mm |

| Thermocouple Location | type J or K are available |

| Insulation resistance (cold) | ≥ 500 MΩ |

| Maximum leakage current (cold) | ≤ 0.5 mA |

Feature of Cartridge Heater Element

- Tube diameter: Φ1mm-Φ32mm

- Tube Material: SS304, SS316, SS321 and NICOLOY800 etc

- Insulation Material: High-purity MgO

- Conductor Material: Ni-Cr or Fe-Cr-Al Resistance Heating Wire

- Wattage density: high/middle/low (5-25w/cm2)

- Lead Connection Option: Crimped or Swaged leads

- Lead wire type: 10″ Standard (Teflon/silicone high temperature fiberglass)

Application of Cartridge Heater Elements

- Injection moulding – Internal heating of nozzles

- Hot runner systems – Heating of manifolds

- Packaging industry – Heating of cutting bars

- Packaging industry – Heating of hot stamps

- Laboratories – Heating of analytical equipment

- Medical: Dialysis, Sterilization, Blood Analyzer, Nebulizer, Blood/Fluid Warmer, Temperature Therapy

- Telecommunications: Deicing, Enclosure Heater

- Transportation: Oil/Block Heater, Aircraft Coffee Pot Heaters,

- Food Service: Steamers, Dish Washers,

- Industrial: Packaging Equipment, Hole Punches, Hot Stamp.

|

|

|

|

|

|

|

|

ackaging & Shipping

Shanghai PAMAENS Technology Co., Ltd located in Shanghai, specialized in researching, developping and manufacturing heaters, plastic machinery accessaries and energy saving products. We have strong researching and developping team, many of our engineers have more than ten years experience on manufacturing heaters, and we have stict quality control system, and a team of professional sales people, so no matter manufacturing process, products quality, or prices, we believe few factories could compare with us in China.

- Diameter

- Length

- Voltage

- Power

- Lead & Fitting (connection and fitting type, leads length)

- Quantity