|

Specification |

|

|

Item Name |

|

|

Item No. |

PM-CHE |

|

Voltage |

6-480 V |

|

Wattage |

Customized |

|

Wattage density |

1w-25w per square centimeter |

|

Dimensions |

Customized |

|

Max. Operation Temp: |

700 Deg C |

|

Diameter tolerance |

-0.1mm |

|

Length tolerance |

+/- 1 mm |

|

Wattage tolerance |

+/- 5 w |

|

Cold part length |

5-10 mm (could be customized) |

|

Certificates |

CE, RoHs |

|

Packaging |

B lister packing with carton box / fumigation free wooden cas |

|

Warranty |

One Year |

|

Material |

|

|

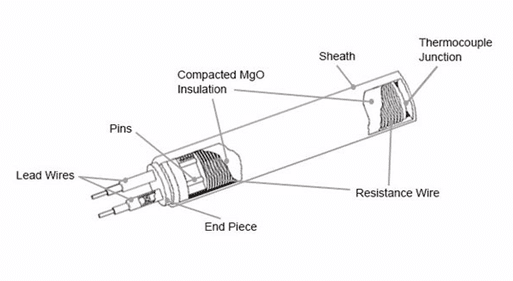

Resistance Wire |

Cr20Ni80, high quality Swedish resistance wire is avalible |

|

Insulation |

Compacted magnesium Oxide, high purity |

|

Sheath material |

SUS304/SUS316L/Incoloy 800/Titanium etc |

|

Lead wire |

Pure nickle glass fiber wire, silicone wire, stainless steel braided wire ect |

|

Types: |

Heater cartridge with internal connection & external connection |

|

Accessories Information |

|

|

Built in thermocouple |

K type or J type |

|

Thread/flange |

Thread or flange is available |

|

Introductions of Cartridge Heating Element |

|

|

Cartridge Heating Element (electric heating pipe) is made of metal tube (including stainless steel and incoloy tube), along the central axis of the tube, the spiral electric alloy wire (nickel chrome, iron chrome alloy) are uniformly distributed. The gap fills compacted magnesium oxide with good insulation thermal conductivity performance, the nozzle ends sealed with silicone, this metal armored heating elements can heat the air, metal molds and a variety of liquids. |

|

|

The feature of Cartridge Heating Element |

|

|

Tube diameter: Φ3mm-Φ30mm |

|

|

Tube Material: SS304, SS316, SS321 and NICOLOY800 etc |

|

|

Insulation Material: High-purity MgO |

|

|

Conductor Material: Ni-Cr or Fe-Cr-Al Resistance Heating Wire |

|

|

Wattage density: high/middle/low (5-25w/cm2) |

|

|

Lead Connection Option: Crimped or Swaged leads |

|

|

Lead wire type: 10″ Standard (Teflon/silicone high temperature fiberglass) |

|

|

The applications of Cartridge Heating Element |

|

|

Injection moulding – Internal heating of nozzles |

|

|

Hot runner systems – Heating of manifolds |

|

|

Packaging industry – Heating of cutting bars |

|

|

Packaging industry – Heating of hot stamps |

|

|

Laboratories – Heating of analytical equipment |

|

|

Medical: Dialysis, Sterilization, Blood Analyzer, Nebulizer, Blood/Fluid Warmer, Temperature Therapy |

|

|

Telecommunications: Deicing, Enclosure Heater |

|

|

Transportation: Oil/Block Heater, Aircraft Coffee Pot Heaters |

|

|

Food Service: Steamers, Dish Washers, |

|

|

Industrial: Packaging Equipment, Hole Punches, Hot Stamp. |

|

|

RFQ |

|

|

1. Diameter |

|

|

2. Length |

|

|

3. Internal connection or external connection |

|

|

4. Voltage & wattage |

|

|

5. What type of lead wire and it’s length |

|

|

6. Quantity |

|

- Email Support beth@pamaens.com

- Call Support +86 021-34125536