Introduction of Heater and Cooling System for Extrusion Blow Molding

Heater and Cooling Systems for Extrusion Blow Molding are mainly suitable for fully extruded parts. They are combined of several heaters with cooling system. According to the applications, the main parts can be combined into one system, as the extrusion cylinder is completely covered, the temperature will be uniform, and at the same time it has a bigger radiation area. It can also eliminate the frictional heat caused by extrusion. As the ceramic beads have good conductivity, using it as insulator, the heater could heat up and cool down faster and more efficiently. This heater is recommended for customers with high cost performance requirements.

Applications of Heater and Cooling System for Extrusion Blow Molding

(Especially for Products which are sensitive to temperature.)

Plastic Extrusion

Injection Molding

Blow-Molding

Pressure Molding

Structural Foam

Food Industry

Container Pipe and Tank Heating

Packaging

Chemical, Oil & Gas Industries

Types of Heater and Cooling System for Extrusion Blow Molding

Air cooled ceramic heater

Air cooled mica heater

Air cooled aluminum heater

Air cooled ceramic heater with ceramic fins

Air cooled ceramic heater with copper fins

Air cooled ceramic heater with nickel plated copper fins

Features of Heater and Cooling System for Extrusion Blow Molding

These Fins are available in width of 45mm, 60mm & 75mm.

Aluminium Fins take 25% & Copper fins takes 35% less time to reach set temperature of 350° C than standard Fins.

Aluminium Fins take 30% & Copper fins takes 35% less time for cooling from 350° C to 100° C than standard Fins.

If working temperature requirement is around 300° to 350° C, it is recommended to use Aluminium Fins as it is cost wise economical.

Aluminium & Copper cooling fins have a maximum operating temperature of 450° C.

These fins can also be used in mounting between heaters as cooling fins.

Advantages of Heater and Cooling System for Extrusion Blow Molding

To heat and cool the barrel

Low Maintenance

Easy Replacement

Improves Quality of finished products

Space Saving

Increases Productivity

Available with Various Diameter, Length, Voltage, Wattage and Configurations.

Perforated heater with fins to provide faster cooling.

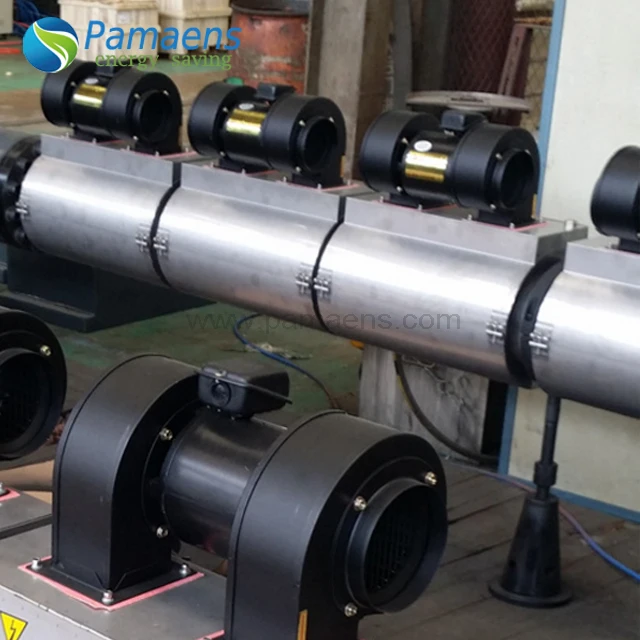

Reference pictures of Heater and Cooling System for Extrusion Blow Molding

|

|

|

|

|

|

|

|

|

|

Fumigation free wooden case or paper box for Heater and Cooling System for Extrusion Blow Molding.

Order Guidance of Heater and Cooling System for Extrusion Blow Molding

- Width/diameter and Length

- Voltage

- Power

- Lead wire type and length

- Quantity