Introduction of hot runner system for injection machine

PAMAENS hot runner systems for injection machine are with optimal reasonable size design, high quality and high heat conducting performance steel, using professional designed high quality imported heating elements to ensure heating fast, precision temperature control(tolerance up to ±1Cº), sealing gate size tolerance controlled within ±0.01MM to make sure customer install and use correctly.

Advantages of hot runner system for injection machine

1. No drainage opening material is used in our hot runner system, which greatly saves the cost of raw material as we do not need cutting drainage openings and scrap and at the same time which make sure our hot runner system has a nice and precise shape.

2. Using our hot runner system, the products will be more sophisticated, and quality can be controlled easier.

3. Our hot runner system shortens the time of release to improve the production efficiency. Comparing to cold runner system, the production efficiency could be increased 30% to 50%.

4. Reduced injection pressure and products internal stress etc..

Applications of hot runner system for injection machine

1. Plastic materials:

Hot runner mold has been successfully used in the processing of plastic materials. Such as PP, PE, PS, ABS, PBT, PA, PSU, PC, POM, LCP, PVC, PET, PMMA,

PEI, ABSPC etc. Hot runner system can be used anywhere cold runner system is used.

2. The size and weight of parts

The minimum weight of the parts or accessories made by hot runner mould could be less than 0.1g, and the maximum weight could be more than 30kg. So its application is very wide and flexible.

3. The industrial field:

Hot runner mold are widely used in the electronics, automotive, medical, daily necessities, toys, packaging, building, office equipment etc. various industrial sectors.

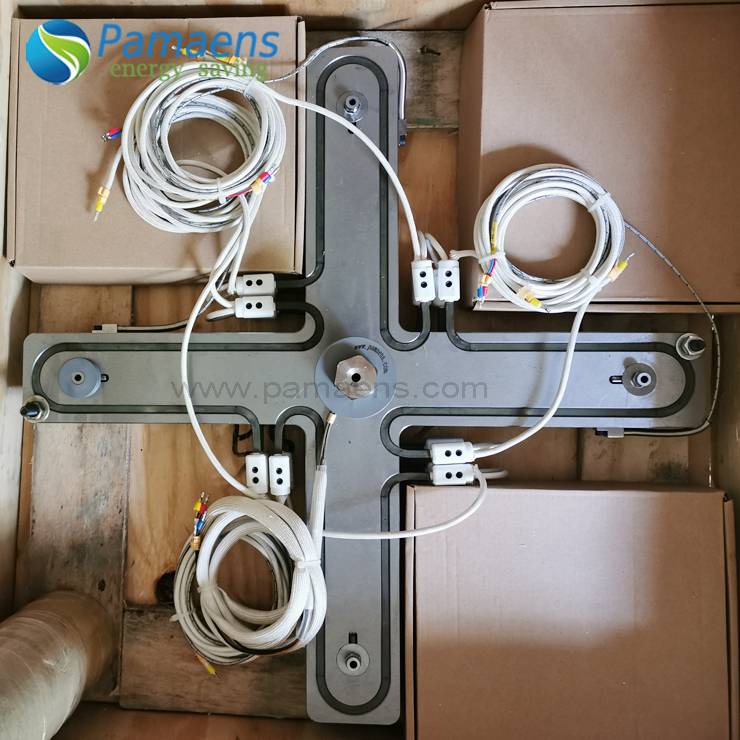

Reference pictures of hot runner system for injection machine

|

|

|

|

|

|

|

|

Please provide specific drawings or samples. All the sizes should be accurate to 0.01mm.

Shanghai PAMAENS Technology Co., Ltd located in Shanghai, specialized in researching, R&D and manufacturing heaters, plastic machinery parts and energy saving products. We have strong R&D team, many of our engineers have more than ten years experience on manufacturing heaters, and we have strict quality control system, and a team of professional sales people, so no matter manufacturing process, products quality, or prices, we believe few factories could compare with us in China.

-

High Quality Standard Hot Runner Mold for Injec...

-

Hot Runner System for Injection Machine

-

High Quality Hot Runner Nozzle Tip Customized

-

High quality standard Hot runner manifold with ...

-

Coil Heater

-

Spring Coil Heater

-

Coil Heater Elements

-

Nozzle Coil Heater

-

Encased Coil Heater

-

Flat Coil Heater

-

Hot Runner Coil Heater

-

High Quality Hot Runner System Nozzle Produced ...