Injection Molding Machine Ceramic Band Heaters are specifically designed for high operating temperature applications. The external temperature of a ceramic band is approximately 400°F while the operating temperature can reach approximately 1400°F. Ceramic bands are manufactured with a stainless steel cover and are fiber insulated preventing heat loss making them highly energy efficient and reducing operating costs. The interlocking ceramics make these heaters flexible, less prone to expansion problems and with a good thermal conductivity, the fitting around a barrel is less critical than a Mica band. Ceramic Barrel Heater Bands are easy to install and have a long functional life.

Applications of Injection Molding Machine Ceramic Band Heater

Plastic Extrusion

Injection Molding

Blow-Molding

Pressure Molding

Structural Foam

Food Industry

Container Pipe and Tank Heating

Packaging

Chemical, Oil & Gas Industries

Specifications of Injection Molding Machine Ceramic Band Heater

Sheath temperature: up to 1000°F

Maximum watts per square inches are determined by the diameter, width and application.

Manufactured with steatite ceramics

Also available in High Temperature (HT)

HT Ceramic heaters are coiled with Cr20Ni80 wire

Operating temperature for HT is 1200°F up to a maximum of 1400°F.

Unaffected by expansion of cylinder being heated

Easy to install – open up and wrap around cylinder

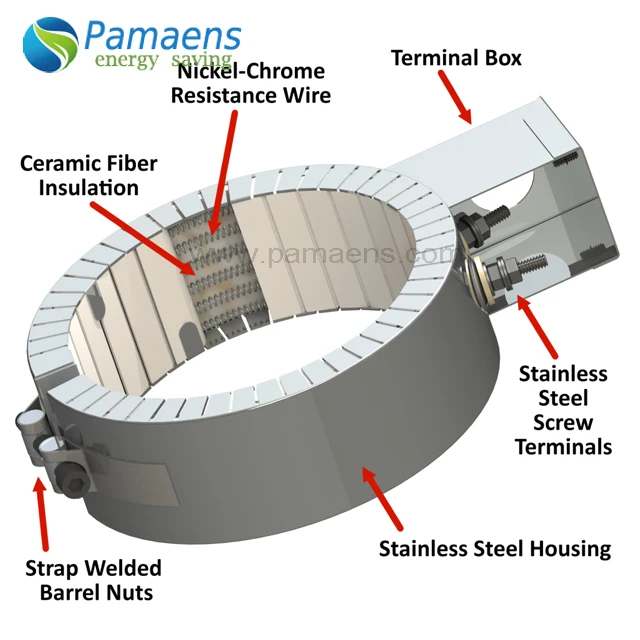

Construction of Injection Molding Machine Ceramic Band Heater

1- or 2-piece construction

Partial coverage

Exterior cover: 24 gauge 3042b stainless steel

A shroud of 26 gauge 3042b stainless steel is placed on inside for protection

Minimum standard diameter: 2″ (consult factory for smaller diameter)

Minimum standard width: 1″ (consult factory for smaller width)

Thickness: 0.5″

Regular gap: 0.375″

Electrical connections of Injection Molding Machine Ceramic Band Heater

Post terminal

Fiber glass sleeve

Metal braid (SS)

Armour cable (AC)

Teflon leads

Silicone wire

Ground post

Dual voltage

Low profile cap

3 Phase

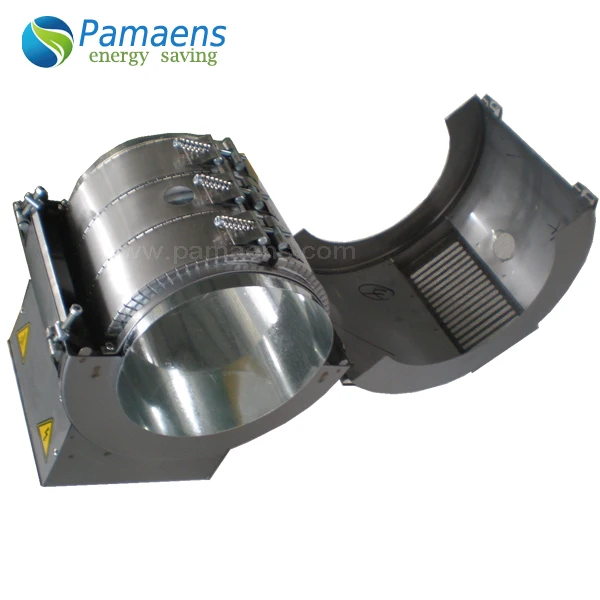

Reference pictures of Injection Molding Machine Ceramic Band Heater

|

|

|

|

|

|

|

|

Shanghai PAMAENS Technology Co., Ltd located in Shanghai, specialized in researching, R&D and manufacturing heaters, plastic machinery parts and energy saving products. We have strong R&D team, many of our engineers have more than ten years experience on manufacturing heaters, and we have strict quality control system, and a team of professional sales people, so no matter manufacturing process, products quality, or prices, we believe few factories could compare with us in China.

Order Guidance of Injection Molding Machine Ceramic Band Heater

- Width/diameter and width

- Voltage

- Power

- Lead wire type and length

- Quantity

How can I get the sample to check your quality?

After price confirmation, you can require for samples to check our product’s quality. If you just need a blank sample to check the design and quality. We will provide you sample for free as long as you afford the express freight.

What can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

What is your term of delivery?

We accept EXW, FOB or C&F Shanghai, DDU etc. You can choose the one which is the most convenient or cost effective for you.

What about the lead time for the mass production?

Our production time is 10-20 days depends on the order quantity and the season you place the order.