Coil Nozzle Heaters are made of nickel chrome resistance wire placed inside chrome nickel steel tube filled with MgO powder and compacted for faster and efficient heat transfer. The hot runner heaters are annealed to acquire malleability for bending into any shape. Injection molding coil heaters with thermocouples are available.Coil heaters could be coiled, to form coil heaters that are ideal whenever a large amount of heat is required in a confined space. Coil heaters have many applications but are mostly utilized as powerful heating cells inside hot runner nozzles in plastic injection molding.

| SPECIFICATIONS FOR COIL HEATER | |||

| Item No. | PM-CH | ||

| Wattage | Customized | ||

| Voltage | 6-480 V | ||

| Working Temperature | Intermittent operating max. temp | 1500°F (815°C) | |

| Continuous operating temp | 1200°F (649°C) | ||

|

Dimension

|

Cross section size | 3.0 x 3.0, 3.30 x 3.30, 3.5 x 3.5, 4 x 4, 4.20 x 2.20, 4.20 x 2.50 etc | |

| Coil diameter tolerance | -0.1mm to -1mm | ||

| Length tolerance | +/- 1 mm | ||

Main Features

1) Intermittent operating temperatures to 1500°F (815°C)

2) Rapid heating and cooling due to low mass construction

3) Heating elements sealed from contamination

4) Stainless steel sheath for corrosion resistance

5) Optional internal thermocouple for temperature control

6) Continuous operating temperatures to 1200°F (649°C)

|

Coil heaterName: coil heater / nozzle heater / spring heater Brand: PAMAENS Material: 1. Cr20Ni80, high quality Swedish resistance wire is available 2. High purity compacted magnesium Oxide 3. SS304 / SS316 / INCOLOY 4. Nylon,metal braided,fiberglass ,silicone rubber, kevlar |

|

Encased coil heaterName: encased coil heater |

|

Coil heater with coverName: Coil heater with SS cover |

|

Flat coil heater

Name: Flat coil heater

|

Pre-Sales Service

- Flexible MOQ

- Fast and on-time delivery (normally within 15 days)

- Free replacement if any quality issues within guarantee period.

- After-sale services

- OEM and ODM service

After-Sales Service

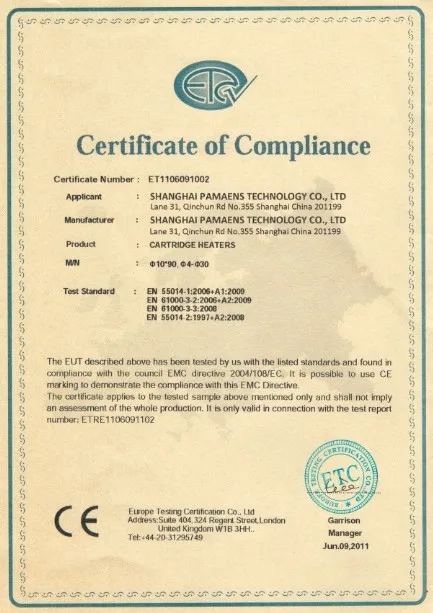

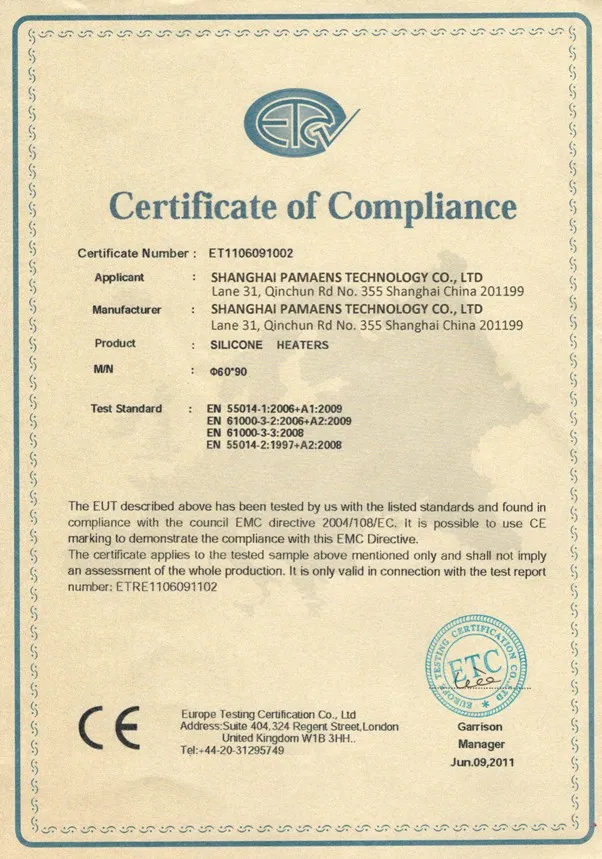

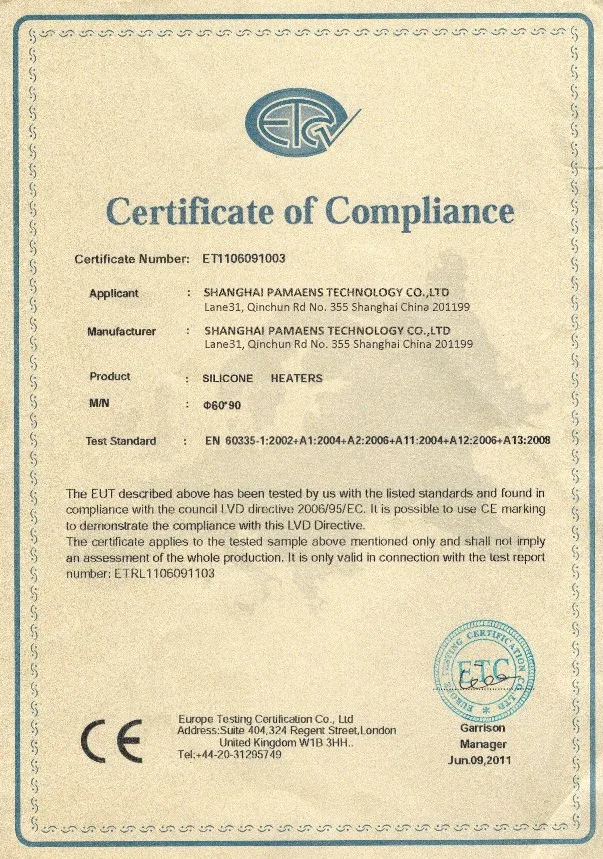

PAMAENS has strict quality control system on material sourcing, manufacturing processing, and products testing. We insist on using high quality raw material and inspect all the materials we will use. We do 100% product testing before shipping, the test includes x-ray inspection, rated power and voltage testing, cold insulation resistance test, leakage testing, pressure test, surface temperature uniformity and various electrical testing.

We provide one year warranty for most of our products, free replacements or refund could be applied if our customers have any quality problem within one year.